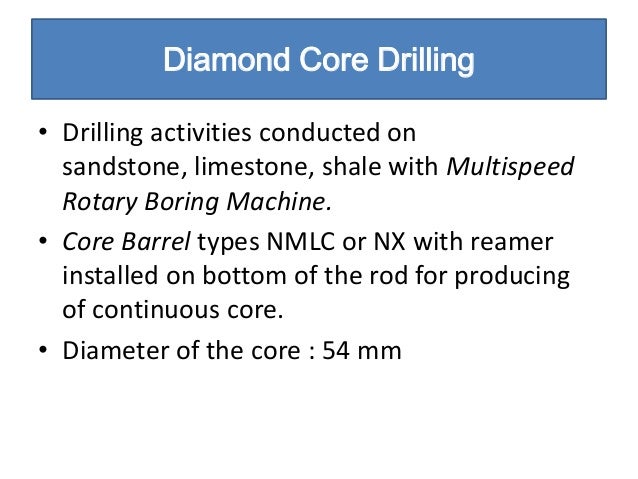

Diamond core drilling is a unique type of drilling that uses a rotary drilling non percussive method of drilling the drilling systems usually include 110v powered motors but can be 415v hydraulic and or air driven systems.

Diamond core drilling method.

If using diamond core drilling added costs will include core bits drilling additives fuel and.

Drilling upto such large depths is not required in coal mining areas where the maximum drilling depth is upto 1000 m as coal mines.

Diamond core drilling utilizes less equipment than rc drilling but is more expensive because it is a time consuming process taking approximately 5 times as long to drill an equivalent amount of rock with diamond core drilling as with rc drilling.

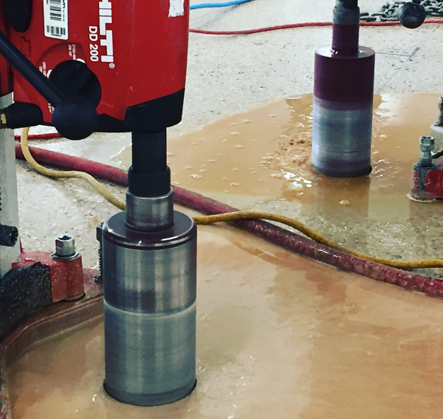

Diamond drilling uses drill bits made of industrial diamonds.

The stone bit is turned carefully and in the same time it s lubricated with water to stop overheating.

Diamond drilling method is suitable for drilling at any angle to obtain cores of friable strata as well as the hardest rock.

Where possible it is preferred over rab percussion rotary air blast drilling drilling and unlike the diamond drilling method which withdraws a small diameter core of rock from the orebody air core drilling is much faster and more cost effective.

Diamond core drilling is a more accurate faster and more efficient method of drilling concrete masonry steel and asphalt structures.

This drill bit is made up of a group of small industrial grade diamonds set into a metallic soft matrix.

As diamond is the hardest naturally occurring material in the world it is ideal for creating openings in a range of materials including concrete metal and glass.

It is composed of industrial diamonds set into a soft metallic matrix.

The drilling technique doesn t cause any damage or vibration to the surrounding structure.

A diamond core drill bit is used by the drilling method repaired for the end of drill pole in the drilling unit or equipment.

Air core drilling is an inexpensive method of exploration drilling that can be employed when safe removal of sample material is paramount.

Exploration diamond drilling differs from other geological drilling see drilling rig in that a solid core is extracted from depth for examination on the surface the key technology of the diamond drill is the actual diamond bit itself.

As shown in the figure the diamonds are scattered throughout the matrix and the.

Diamond drilling allows for the removal of solid cylinders of rock core from deep within the earth.